Production Stage manufacturer selected

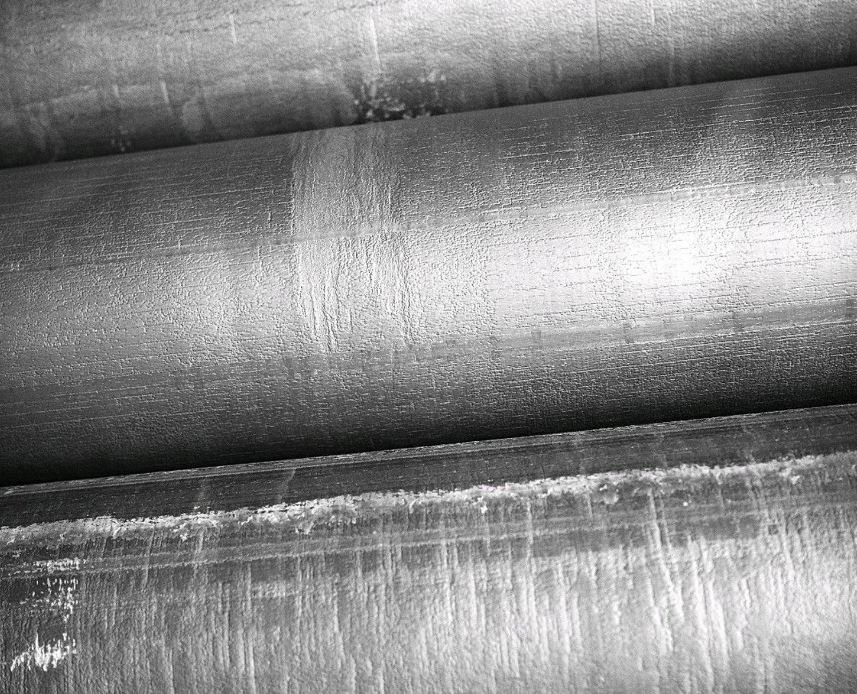

We are delighted to announce the start of our partnership with Norsk Hydro who will manufacture our Production Stage aluminium channel.

The channel is being fully made in the UK, with the extrusion undertaken in Cheltenham, the anodisation process in Bedwas and locking mechanism assembly in Swansea.

Charge Gully was designed from inception as an aluminium extrusion. To melt aluminium and recycle it into a different product with the same properties is simple and consumes just a fraction of the energy used to manufacture it. Recycling aluminium saves 97% of greenhouse gas emissions produced in the primary production process (source: Innovate UK https://iuk.ktn-uk.org/perspectives/circular-economy-for-aluminium-beyond-recycling/).

We have gone even further by selecting the Hydro Restore aluminium range which is made from a combination of recycled pre-consumer scrap, recycled post-consumer scrap and primary aluminium. The aluminium range releases up to 5x less CO2 emissions than the global average of aluminum production.

If you would like more information about the production process, just drop us a message and we will be delighted to send more details.